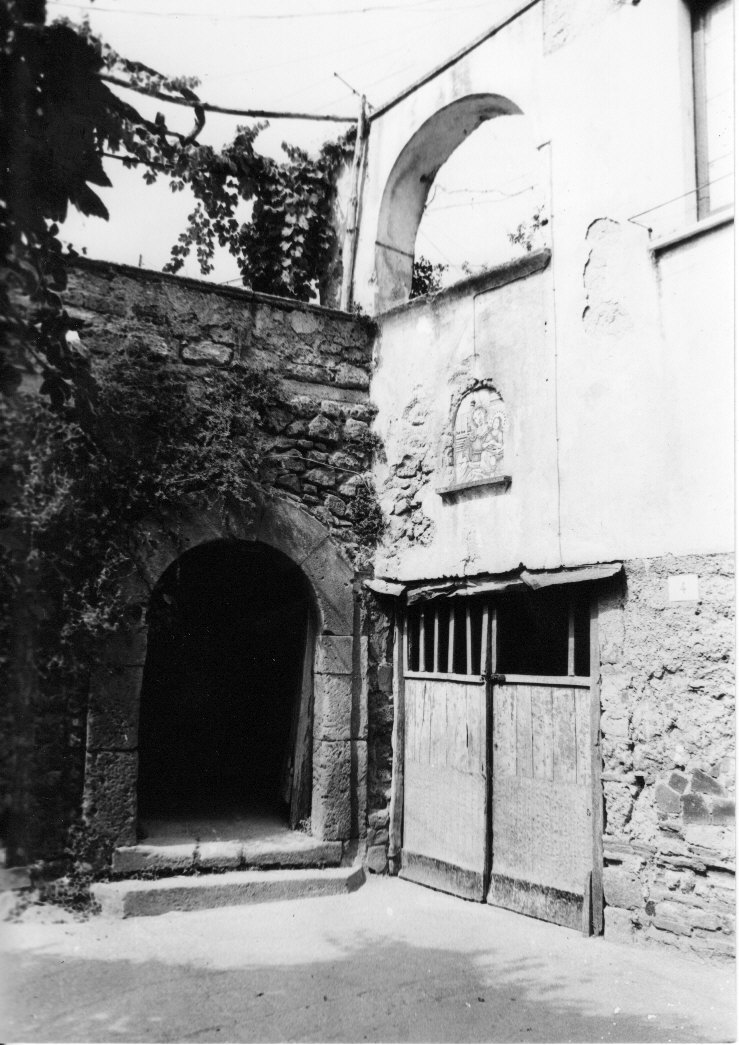

Even a few decades ago, children usually played among the large piles of clay dispersed in every corner of the hamlet. Everywhere, in its characteristic alleys, the hamlet of Maiano, one of the five districts of Sant’Agnello, revealed the importance of the terracotta manufacturing for the subsistence of its inhabitants.

Everything linked to the eruptions of the large coastal volcanoes, whose pyroclastic materials had reached the Sorrentine Peninsula, settling on the original karst rocks. The particular properties of that land made the products of Maiano special. From the tiles covering the roofs of Sorrento and the Coast to the bricks, put to dry by the thousands along the tuff walls of the ancient houses, up to the lathe objects and the terracotta pipes. But above all the flat bricks, the famous biscuits of Sorrento, used in the fireplaces and in the traditional wood ovens. The “secret” of the best Neapolitan pizza, known and recognised by the experts worldwide.

Therefore, it is precisely the clay of Maiano that makes the difference. Collected and processed according to the methods handed down over the centuries from generation to generation. A long and delicate production process that starts in the citrus groves, another excellence of the territory, by virtue of the consolidated agreement in the last three centuries between farmers and those working with clay. It is in the fields that you can see the right land, extracted by hand from deep pits, dug between orange trees and lemon trees. In those holes the ashes and the waste materials of the furnaces also end up there, before the planting of other young trees, which can extend their roots deeper and grow more luxuriant. Not casually, in the nineteenth century, when the handicraft of terracotta in Maiano was particularly flourishing, there was also a considerable increase of oranges production, dominating at that time, and lemons. All the clay objects and fruits are all widely exported, outside the Peninsula.

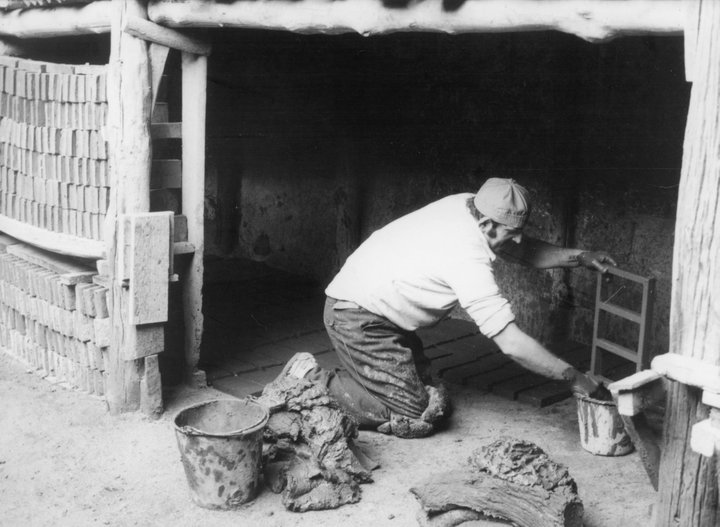

Once excavated, the clay soil is crushed and reduced into fragments, before being decanted in water, and to be then mixed to another dry earth, until obtaining a mixture that, after a day, is carefully manufactured. This was then improved over time. Skills acquired since childhood, those working with clay followed until few decades ago all the phases of the manufacturing rigorously by hand, using a few family tools, inherited from the past. Like the forms to create bricks for ovens, defined in slang “suoli” “grounds” . Even mentioned for the first time in 1492, in a registration document of the transport to Naples of eighty “sola de furno” “oven grounds”).

The first desiccation takes place in the sun, then the decisive passage in the oven. Following the ancient techniques, practiced by the Greeks and then by the Romans. Who have left important traces of their presence in Maiano. Once it comes out the oven, the biscuit of Sorrento has definitively acquired the characteristics which make it unique: thanks to the strong presence of silicon of the volcanic clay, it is very porous, it warms up rapidly in contact with fire and retains the heat for a long time. This is ideal to guarantee a perfect cooking of pizza, without burning.

Working the clay is one of the most ancient profession of the Peninsula. The main one in Maiano, where there were several families owning furnaces. The industrialization of material productions for the construction industry in the second half of the twentieth century has severely hit the artisan activity of Sant’Agnello hamlet, which has suffered a progressive depopulation and abandonment. Today, only a couple of families continued the tradition. However, the potentialities to relaunch the handicraft of Maiano terracotta is all there, through the recovery and the transmission to the young people interested in the precious heritage of technical knowledge and practice of clay processing, which otherwise risk being lost within a few generations. Meanwhile, the biscuit of Sorrento made in Maiano remains fundamental for the real Neapolitan pizza. The good one, a Unesco heritage…

Comments powered by CComment